Are you gearing up to install underfloor insulation for your home before winter arrives? If…

Understanding the new H1 Regulations for Concrete Slabs

Insulation in concrete slab flooring plays an important role in the thermal performance of the floor, preventing energy transfer between the slab and the ground it sits on. Acting as a moisture barrier, it prevents condensation on the slab surface and guards against mould and moisture entering the slab. Insulation also protects the concrete slab from extreme temperature fluctuations, minimising the potential for cracks and damage to occur over time.

It’s important to specify the right insulation for concrete slabs so that the building is as energy efficient as possible and the concrete slab is protected.

In May this year, the H1 clause of the NZ Building Code was updated to improve the insulation of buildings and reduce the energy required to heat them. Insulation for flooring is included in this clause, and changes to the regulation will also impact the materials specified for concrete slab floors.

What are the new R-values and how do these change across the country?

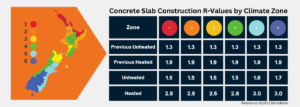

The country has been divided into six climate zones and each zone has a different requirement for the R-value for concrete slab insulation. The previous standards of 1.3 (unheated) and 1.9 (heated) have changed to 1.5-1.7 for unheated concrete slabs, and 2.5-3.0 for heated slabs across Aotearoa.

Why the change to R value is more significant than it looks

The change in R-value from 1.3 to 1.5 might not seem like a big step, however, in real terms the increase is more significant. This is because the way the R-value is calculated changed in the 5th edition of H1/AS1. The new standard states “The requirements for determining the thermal resistance and construction R-value of building elements have been revised to better reflect the thermal performance of windows, doors, skylights and slab-on ground floors.” According to BRANZ, the increase is the equivalent of going to R2.0 under the previous approach. R1.5 means most concrete slabs in buildings under 300m2 will be specified with some combination of perimeter and under-slab insulation.

Use of construction R-values not product R-values

When interpreting the new R-values in H1, it’s important to note that these are construction R-values. While a product R-value refers to the thermal resistance of that product, determined by standardised testing, a construction R-value refers to the overall thermal resistance provided by the combination of insulation materials and construction techniques. When considering the R-value of concrete slabs, the vertical edge insulation and the ratio of area to perimeter are key. For this reason, a solution that considers the combination of both under slab insulation and perimeter edging is an advantage.

Calculating Construction R-Values

There are a number of variables involved in the calculation of construction R-values for concrete slab floors, including the slab area to perimeter ratio. EXPOLs floor slab insulation calculator takes care of the details and provides solutions that meet your R-value requirements. Find the floor slab insulation calculator here.

More than R-values alone

Getting the right R-value to meet the H1 standards is the first step in choosing the right floor slab insulation. In addition to meeting the code requirements, the performance of the product should also be considered. Insulation needs to be highly resistant to moisture, continue to perform over time, deliver a high compressive strength, and limit any environmental impacts. EXPOL’s SLABX200 meets and exceeds these performance criteria, with uncompromised compressive strength of 200kPa @ 10% deformation, exceptional insulation values, high water resistance and with a 20 year product warranty. Our products are also actively recycled into other EXPOL products. You can find out more about EXPOLs concrete floor insulation here or get in touch with our team to answer any questions.