EXPOL THERMASLAB EDGE

HIGH PERFORMANCE SLAB EDGE INSULATION SYSTEM

ThermaSlab Edge is EXPOL’s new generation Slab Edge Insulation System specifically designed to meet new Building Code standards for Concrete Slab Insulation.

ThermaSlab Edge is suitable for retrofit applications. Specifically, engineered for residential and commercial projects, it’s high performance gives engineers and specifiers peace of mind while increasing the thermal performance of the building.

ThermaSlab Edge’s durable nature means it will not degrade over time, keeping its integrity for the life of the structure.

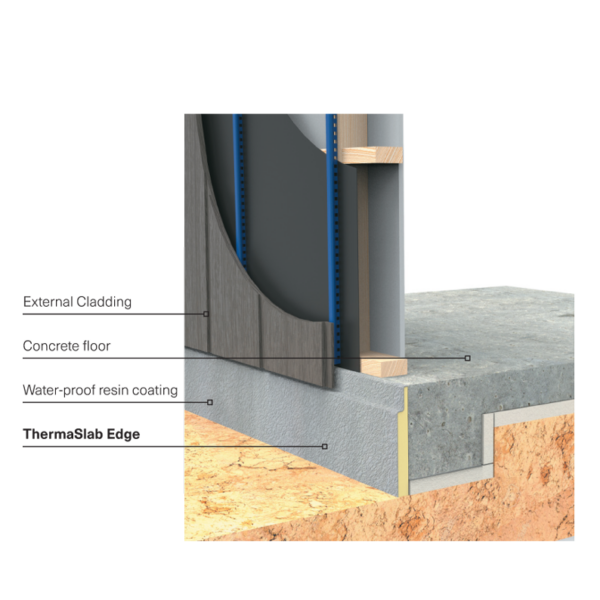

PRE-COATED

With a water-proof resin coating that does not require painting, saving time and money.

CLEAN INSULATION

ThermaSlab Edge is also available as clean insulation, requiring plastering after the concrete pour.

The benefits:

- Increases the thermal performance of a building

- A simple, cost-effective slab edge insulation system

- Designed to meet new H1 standards

- No painting required, saving time and money

- Exceptional insulation values

- High water resistance

- Lightweight and easy to handle

To see how EXPOL Concrete Floor Insulation products are integrated into the new Building Code Changes introduced 1 May 2023 please see the EXPOL FLOOR / SLAB INSULATION CALCULATOR

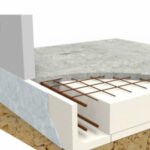

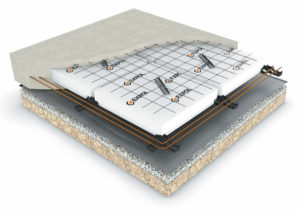

It is used as an insulation solution for floor slab systems:

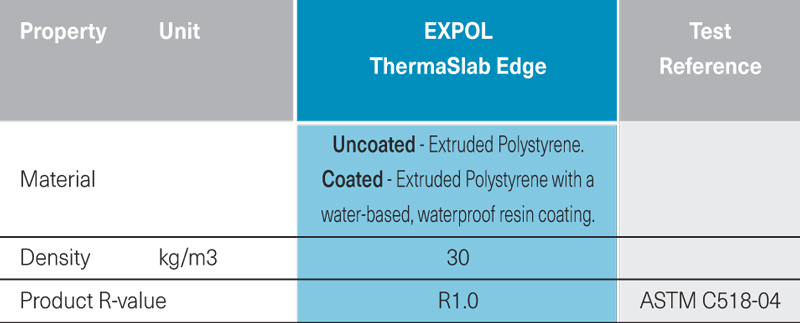

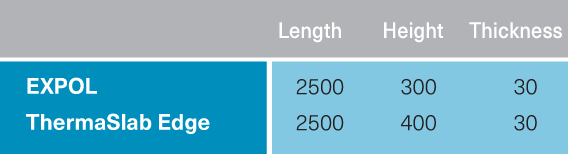

ThermaSlab Edge Technical Specifications

Sheet Sizes (mm)

How to Specify

- Ask your engineer to add EXPOL ThermaSlab Edge to their designs

- Talk to our Tech Team about your project planning

- Visit below for DWG or PDF files

Architects / Specifiers Downloads

INSTALLING EXPOL THERMASLAB EDGE

Please read entire set of instructions before starting.

Ensure surfaces are clean and free from dust, oil and grease.

To assist you, we’ve developed an easy step guide and download pdf – follow it and you can’t go wrong.

Some useful tools for installation

Bonding panels with StyroFix Adhesive

Using EXPOL Patch-Kit

System Components

EXPOL Patch-Kit

A 4 litre pail of our water-based, water-proof resin coating suitable for patching joins.

Styro-FIX Construction Adhesive

Styro–FIX is an advanced single component polyurethane-based construction adhesive.

This powerful adhesive is developed especially for the construction industry and will bond most types of construction materials including timber (damp and dry), concrete, plasterboard, polystyrene and many other porous and non-porous substrates.

It bonds expanded polystyrene to most surfaces, delivers strong adhesion and rapid cure, it is gun-able and non-drip.

FAQs

What is R-Value?

An R-Value is a rating which measures how well insulation can resist heat flow. ‘R’ stands for thermal resistance.

- R-Value level depends on a number of things such as the type

of material, its density and thickness. - Higher R-Value = Better insulation.

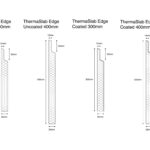

Does EXPOL ThermaSlab Edge come coated and uncoated?

ThermaSlab Edge is available both:

- Coated with a water-proof resin coating that does not require painting, saving time and money.

- Uncoated / as clean insulation, requiring plastering after the concrete pour.

Does EXPOL ThermaSlab Edge come in different heights?

EXPOL ThermaSlab Edge is available in two different sheet sizes:

- 2500x30x300mm

- 2500x30x400mm

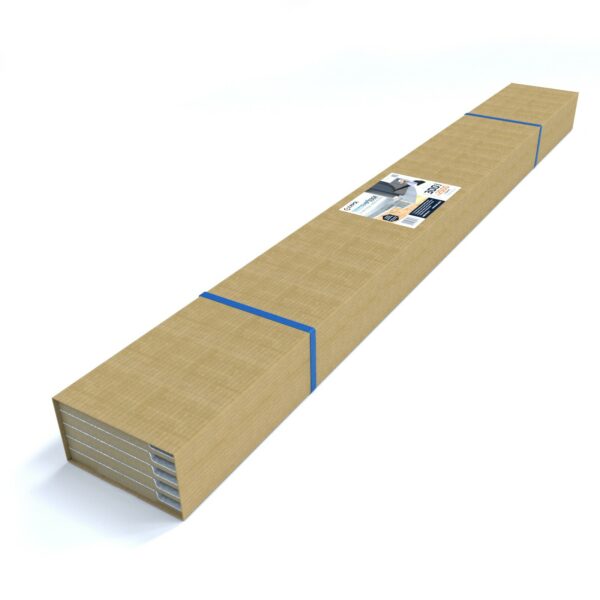

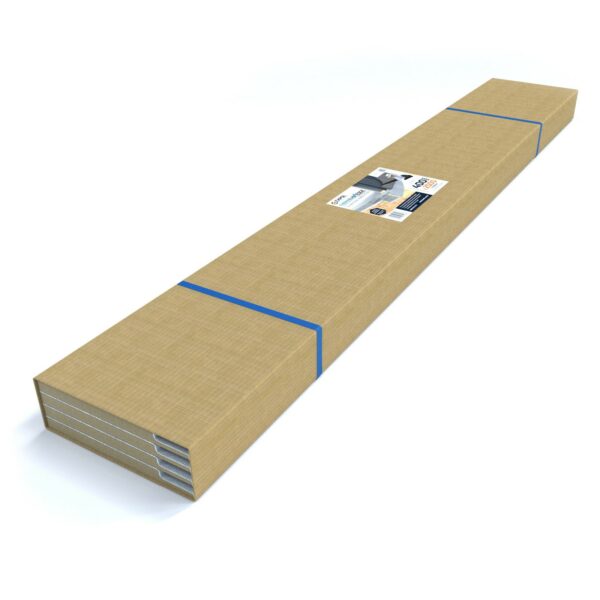

How many sheets of ThermaSlab Edge (Coated) are in a pack?

There are:

- 5 lengths in the 2500x30x300mm pack

- 4 lengths in the 2500x30x400mm pack

How many sheets of ThermaSlab Edge (Uncoated) are in a pack?

ThermaSlab Edge (Uncoated) is available for purchase in individual lengths of 2500mm

What system components will I need?

We recommend the use of:

- Styro-FIX Construction Adhesive (1 tube per sheet of ThermaSlab Edge)

- EXPOL Patch Kit to patch over joins

How do I install ThermaSlab Edge?

Detailed instructions are above.

How many tubes of Styro-FIX will I need?

We recommend using one tube of Styro-FIX per length of ThermaSlab Edge.

Does EXPOL ThermaSlab Edge (Coated) require painting?

No, EXPOL ThermaSlab Edge (Coated) is waterproof and does not require painting. A three-coat acrylic paint finish can be applied to finished products, if desired.

What is the difference between EXPOL ThermaSlab Edge and MAXEdge?

EXPOL ThermaSlab Edge is specifically designed for retrofit slab edge insulation, whereas MAXEdge is specifically designed for in-situ slab edge insulation.

Is ThermaSlab Edge suitable for both slab-on-grade and rib-raft slabs?

Yes, ThermaSlab Edge can be used for both slab types.

Is there an in-situ option available?

Yes – to find out more about MAXEdge, our in-situ Slab Edge Insulation click here.

Is EXPOL ThermaSlab Edge water resistant?

Yes, the water-based coating on EXPOL ThermaSlab Edge is waterproof.

How do I patch up joins or repair damaged areas of EXPOL ThermaSlab Edge?

We recommend use of the EXPOL Patch Kit to patch over joins or repair any damage that occurs during installation.

Where can I purchase EXPOL ThermaSlab Edge from?

Mitre 10, Bunnings, Carters, ITM, PlaceMakers, BuildLink and other Nationwide hardware outlets.

Click here to visit the stockist page.