THE EXPOL RECYCLING PROCESS

The EXPOL recycling process was introduced due to our major financial and moral investment into recycling polystyrene. We operate seven recycling plants nationwide.

The process takes polystyrene waste from all over New Zealand and turns it into new EXPOL products which are marketed under our EXPOL Earth brand. At EXPOL we recycle over 400 tons of polystyrene each year.

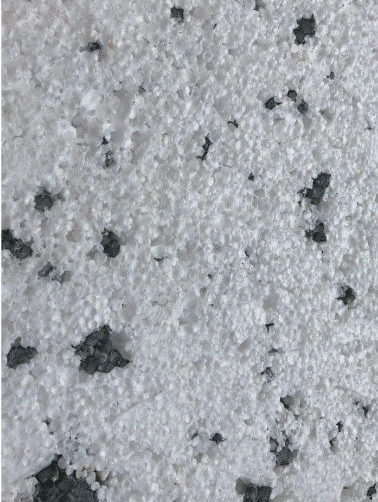

Our recycling process even extracts the dust from the recycled polystyrene and turns it into pellets which in turn used to make new products.

The EXPOL Recycling Process

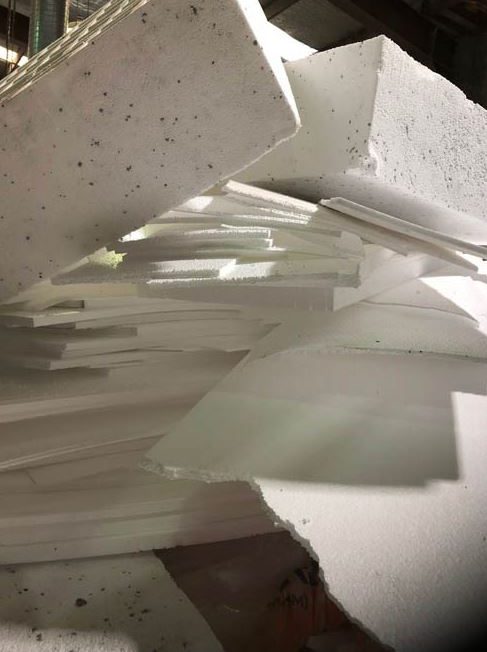

The recycling process takes the polystyrene to be recycled and breaks it down into pieces of polystyrene that then can be made introduced into products we manufacture.

We also produce blocks of recycled polystyrene which are then used to manufacture EXPOL StyroDrain a 100% recycled drainage board.

Taking Responsibility

We encourage our products to be recycled time and time again and we don’t believe in putting a premium price on them.

It is better for the environment if our recycled products are accessible – without the barrier of over inflated prices.